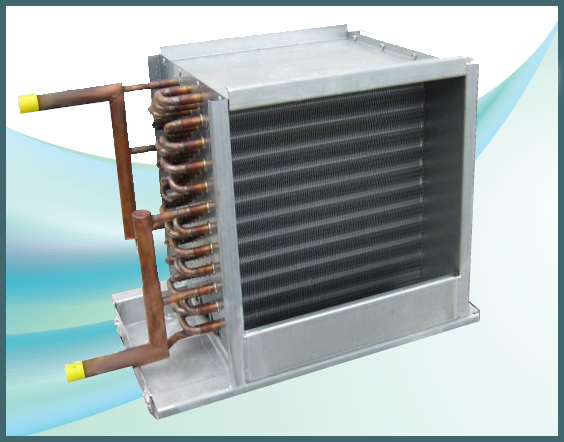

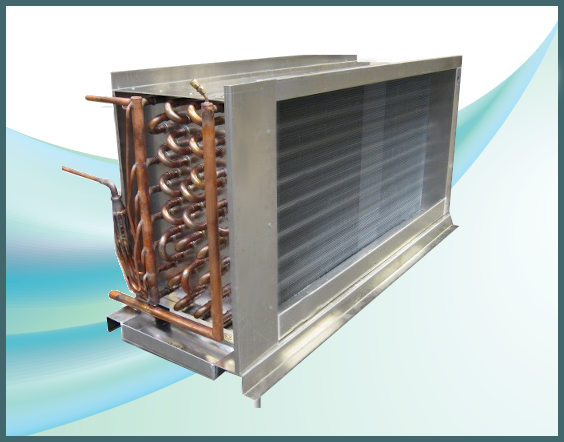

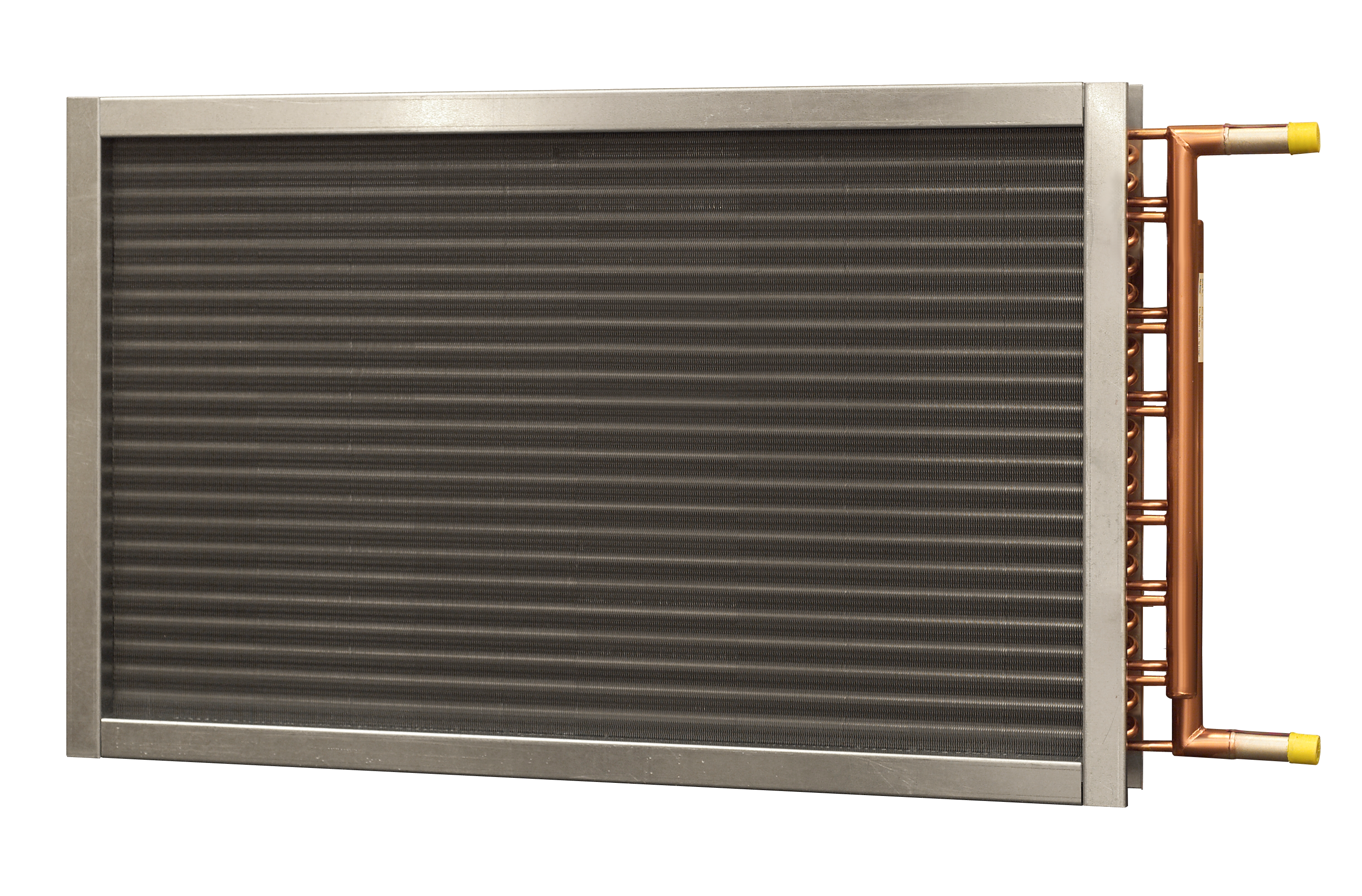

Heating & Cooling coils

EVAPCO offers a great variety of heat exchangers for heating and cooling of air in ventilation systems and for industrial heating and cooling. EVAPCO's heat exchangers are custom-made and can be supplied in many different material combinations. This means that every heating and cooling coil you order through EVAPCO is designed and produced for your specific situation.

This includes a specific selection of materials, fin configuration, fin spacing, number of fans and other relevant unit characteristics. All calculations are made in our own heat exchanger calculation software, CoilCalc, developed by EVAPCO based on more than 30 years of experience in product of coils.

A customer specific solution that fits your company

Because EVAPCO only produces customer specific solutions, you will always get the most optimal ventilation with our service. We have decades of experience in producing unique solutions for many different customers, which has given us a very wide range of areas in which we typically provide service and advice.

EVAPCO has experience in providing heating and cooling coils for use in ventilation systems within these areas:

- Offshore

- Power

- Commercial HVAC

- District heating/cooling

- Dairy and food

- Gas and smoke from exhaust

- Seawater (salt water) and groundwater

- Ammonia

- Corrosive media (corrosive substance)

- High pressure

- Industrial processes

Whatever you need, we can help you produce exactly the solution you need. Our many years of experience in developing ventilation solutions means that we understand your unique situation and create the solution accordingly.

Contact us to learn more about a customized solution for your business.

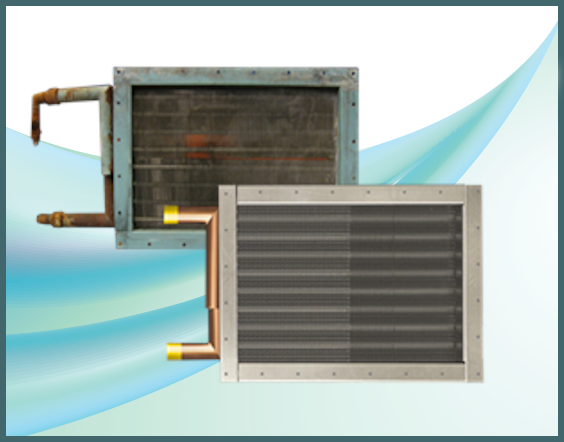

Heating and cooling coils in a flexible range of materials

When you buy heating and cooling surfaces from EVAPCO, everything down to the smallest detail is configured and specialized for your unique situation.

That's why we offer a wide range of different materials, each with advantages and disadvantages depending on the situation in which they are to be used.

Features and benefits of EVAPCO's solutions

- Tailor-made solutions for every need.

- Products developed on the basis of more than 30 years of experience.

- Saving water and energy.

- Reduces noise pollution.

- No need for chemical application for water treatment.

- Our units consist of up to 80% recycled content.

Examples of materials for use in heatexchangers

To give you an idea of our expertise, here is an overview of different material choices for frames, coils and fins:

Frame material

- Galvanized steel (Z-275) - Standard frame material for most solutions

- Alu Zinc (AlZn) - Provides more protection than galvanized steel

- Aluminum Magnesium (AlMg3) - lightweight material that provides extra protection on the surface (e.g. on the surface of AlZn)

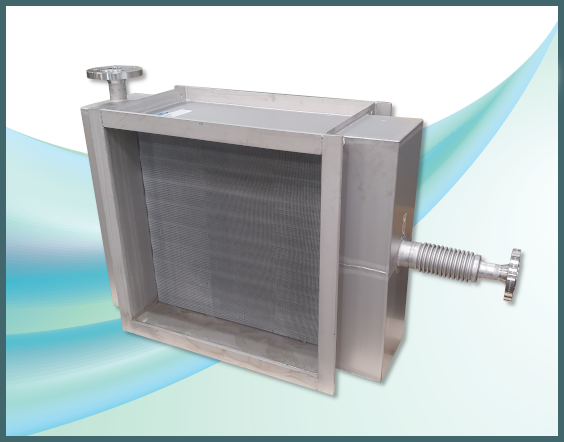

- Stainless steel (AISI 304) - A good choice in corrosive (corrosive) environments

- Stainless steel (AISI 316) - The obvious choice for harsh and coastal areas

Pipes and headers

- Copper (Cu) - Good thermal and corrosive properties for most solutions

- Aluminium (Al) - A good choice for special solutions involving e.g. deionized (demineralized) water

- Stainless steel (AISI 304) - Ideal for corrosive (corrosive) environments or industrial solutions

- Stainless steel (AISI 316) - Typically used in food processing or coastal environments

- Titanium (Ti) - Durable lightweight material ideal for use in cooling systems where salt water is used as a circulating fluid

Fin material

- Aluminum (Al) - Excellent mechanical and thermodynamic properties

- Copper (Cu) - Heavy and corrosion resistant material with good thermodynamic properties

- Tinned copper (CuSn) - Extra protective layer on top of regular copper

- Alu Magnesium (AlMg) - Corrosion resistant material for coastal environments

- Stainless steel (AISI 304) - Ideal for corrosive environments or industrial solutions

- Stainless steel (AISI 316) - Typically used in food processing or more harsh environments where AISI 304 is not resistant enough

- Aluminum Hydrophilic (AlHy) - Ideal for adiabatic systems due to the metal's hydrophilic ("water-loving") properties

- Epoxy Coated Aluminum (AIEP) - An alternative to Alu Magnesium (AlMg), where AIEP is particularly suitable for certain corrosive environments.

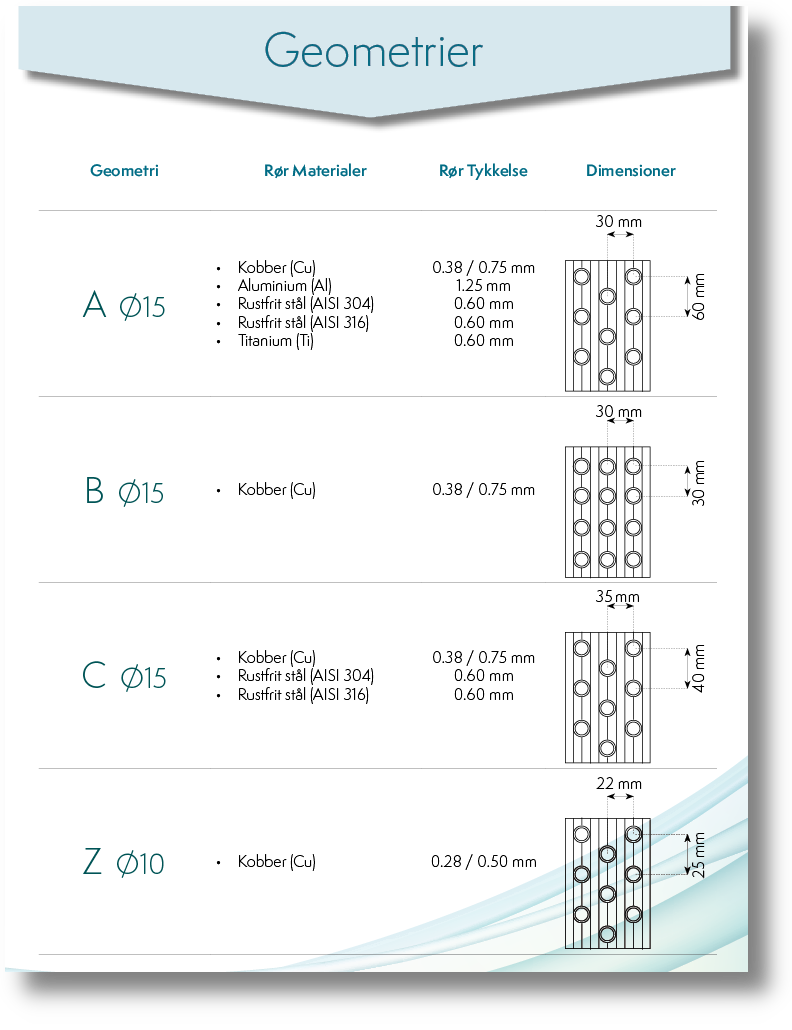

Geometric configuration options

Material selection is based on the solution that best suits your purpose. The same also applies to the design of the solution, where the geometric dimensions of the solution are also tailored to your unique needs. See the overview below for a selection of the geometric dimensions we work with:

Product groups

Downloads