Heat Exchangers

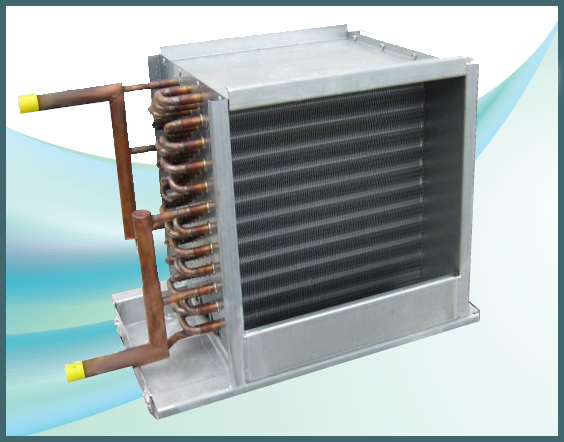

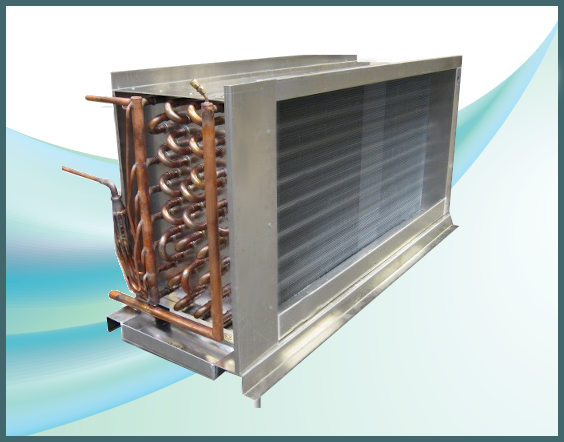

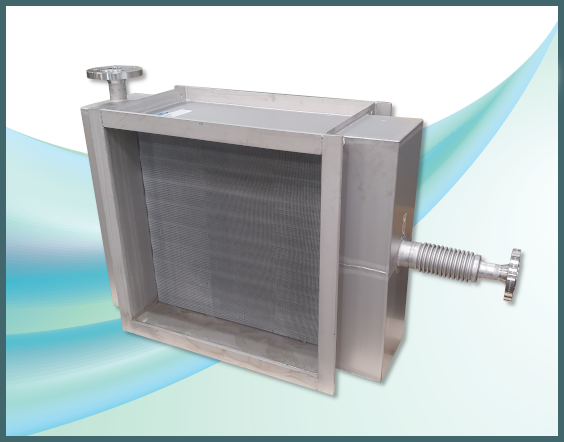

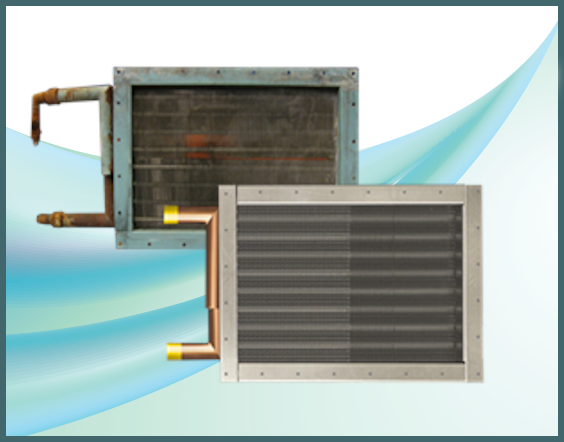

EVAPCO Europe offers heating and cooling solutions for standardized or customer-specific ventilation systems, industrial systems and processes, as well as for commercial purposes. Our cooling and heat exchangers are produced in all shapes and sizez, depending on the application and the customer's wishes, needs and requirements.

All calculations for the production of heat exchangers are based on our own calculation programme, CoilCalc. The software is developed by EVAPCO based on more than 30 years of experience in the production of coils for industrial heat exchangers, dry coolers, condensers, heating and cooling exchangers.

What are industrial heat exchangers used for?

Heat and cold are key elements of a well-functioning company, and with customer specific heat exchangers from EVAPCO, you and your company can achieve your energy goals. This is relevant, for example, in connection with ESG objectives, where a professional setup of efficient heat exchangers can save your company from unnecessary waste.

Efficient heat exchangers for industry enables companies to exchange heat energy from one place to another in a cost-effective way - with the result that energy that would otherwise be lost can instead be transferred and utilized elsewhere.

For example, if a machine that produces a lot of heat energy, you can efficiently utilize this heat energy to heat your premises. In this way, you are utilizing an existing resource in your company that would otherwise be lost to the atmosphere. The result is a considerable saving in energy consumption for heating premises, which can now be partly heated by the energy residues of your own machines.

This goes straight to the financial bottom line. In addition, it also puts your company ahead in environmental accounting, as an efficient and circular use of energy favors the environment and the climate. In this way, efficient heat exchangers for industry can help companies towards achieving certain ESG objectives.

What are commercial heat exchangers used for?

EVAPCO Europe A/S, do not only supply market-leading industrial heat exchange solutions, but our commercial solutions are also among the best on the market.

These solutions are especially aimed at larger family homes and commercial buildings, where there is a need for a heat exchange solution that meets the requirements. When it comes to heat exchange and ventilation systems an all-in-one solution is rarely possible. Therefore, we always design and manufacture our solutions to the specific customer's needs.

A typical need in commercial heat exchange is a need for better comfort and a better indoor climate. If you own a building that serves many people during the day, an optimized ventilation system will provide you with a better indoor climate that enhances concentration/performance and/or improves the on-site experience for the guests.

At the same time, a top-quality ventilation system will mean that you can efficiently store and recover waste heat - which ultimately means less wasted resources that can be directly reflected in future heating bills.

Contact EVAPCO today to learn more about the possibilities to optimize and streamline your current systems - and save on your next heating bills

Sustainable and climate-conscious units for efficient heat transfer

Innovation and climate-conscious sustainability go hand in hand at EVAPCO. Our industrial heat transfer equipment conserves natural resources and helps reduce noise pollution. We are constantly developing new technologies that deliver cost-effective operational benefits to our customers while protecting the planet for future generations.

Features and benefits of EVAPCO’s solutions

- Customer specific solutions for every need.

- Products developed based on more than 30 years of experience.

- Saving water and energy.

- Reduces noise pollution.

- No need for chemical application for water treatment.

- Our units consist of up to 80% recycled content.

Special materials for speciel requirements

Industrial processes or harsh environments require a special material selection, welding and fabrication process to achieve the required quality standards. Harsh environmental conditions may result in standardized heat exchangers of equivalent standard materials not being able to meet or exceed project requirements.

At EVAPCO we understand the importance of meeting the special requirements, this is reflected in our wide range of materials, which allow the most efficient heat or cold exchange to be achieved.

To give you an idea of the range of our expertise, we have created an overview of different material choices for frames, coils and fins. Find the overview on page 4 in our heat exchanger brochure.

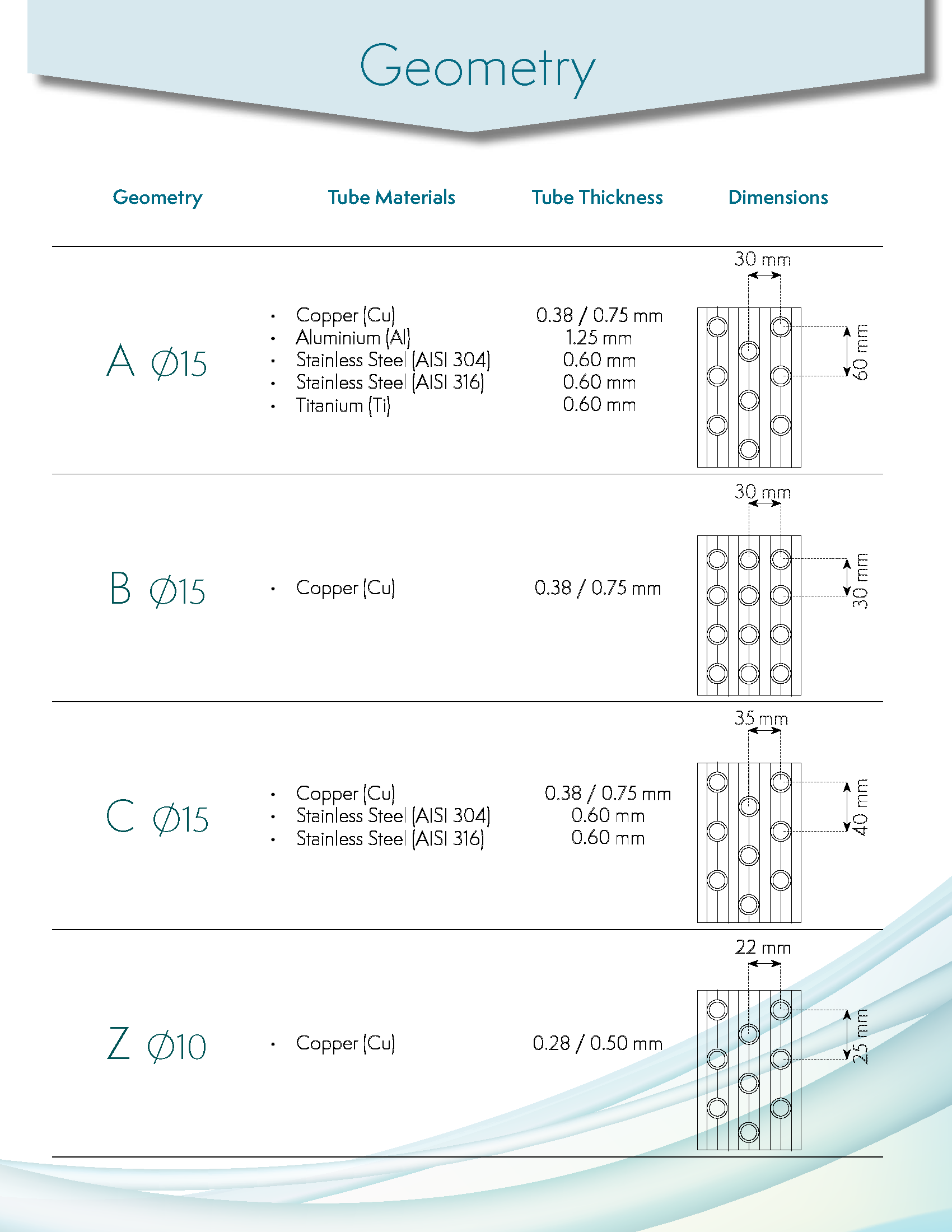

Geometric configurations

Material selection is based on the solution that best suits your application. The same also applies to the design of the solution, where the geometric dimensions of the solution are also tailored to your unique needs.

See the overview below for a selection of the geometric dimensions we work with:

Downloads